Engineering & Design

Capabilities

- Thermal

- Vibrational

- Mechanical

- Structural

- Finite Element Analysis (FEA)

- Wind & Seismic

- Fracture Mechanics

IHZL has expertise in Design including Finite Element Analysis for Process Equipment and Heat Exchangers as per various International codes and standards such as:

Codes

- ASME Section VIII DIV 1

- ASME Section VIII DIV 2

- PD 5500

- TEMA

- AD Merkblatter

- API 660

- EN 13445

- ASME Sec.I

- GOST

- PED

- IBR

- CODAP

Design Software:

- AutoCAD

- Inventor

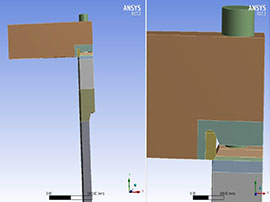

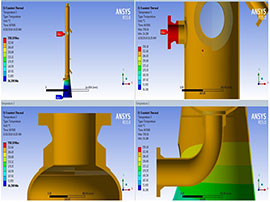

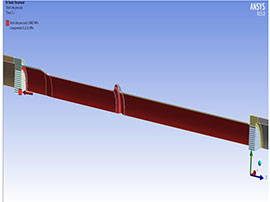

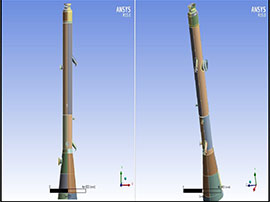

- ANSYS for Finite Element Analysis (FEA)

- PV Elite

- AutoPIPE Exchangers

- Solidworks

- Design code ASME Sec. VIII Div.1, ASME Sec. VIII Div.2, PD5500, French Design code CODAP, German Design code AD MERK BLATTER, European Design code EN13445, Russian Design code GOST R52857 /GOST 34233 & Chinese GB 150

- HTRI

- Staad

Finite Element Analysis (FEA) Team Capabilities:

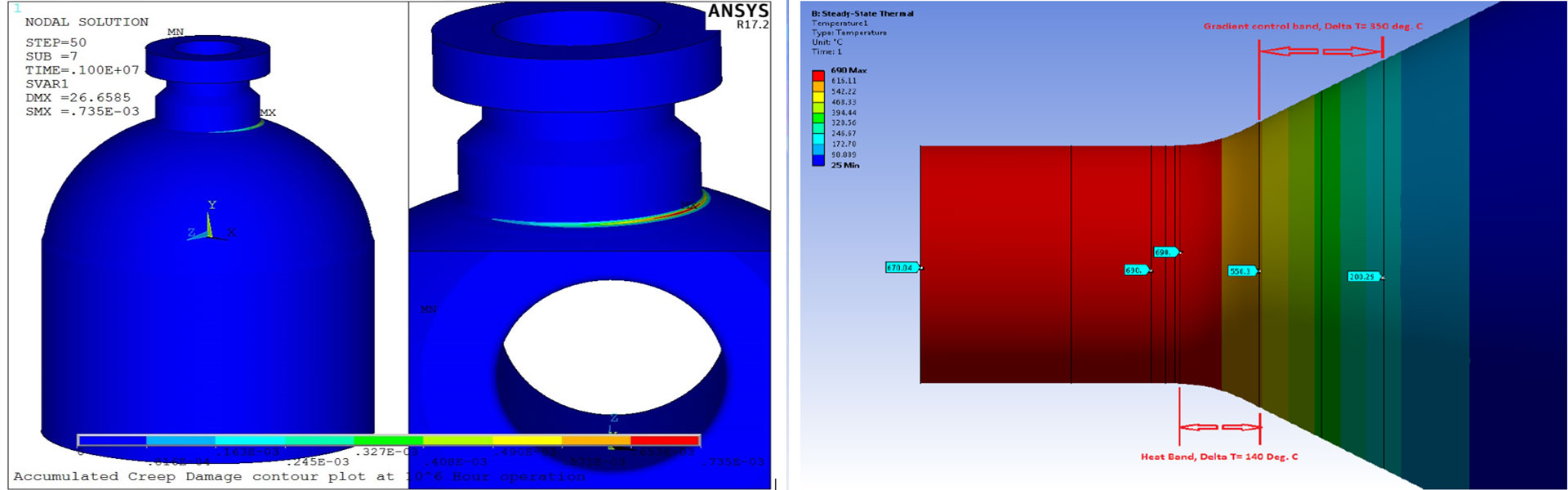

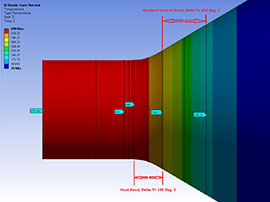

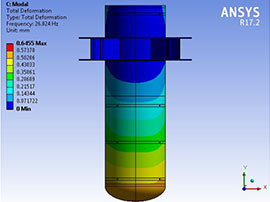

IHZL has well experienced Finite Element Analysis (FEA) team to carry out all Finite Element Analysis (FEA) activities. Finite Element Analysis (FEA) team is having expertise in Modeling, Meshing, Stress Analysis & Stress Categorization to solve all Finite Element Analysis (FEA) problems related to Static Structural, Static Thermal, Transient Thermal, Dynamic Analysis, Low Cycle Fatigue, High Cycle Fatigue, Creep Analysis, Creep Fatigue Interaction, Flange Joint Leakage, Plasticity, Elastic-Plastic Interaction and Response Spectrum Analysis.

Some of the Finite Element Analysis (FEA) handled:

- 3D Analysis of Tubesheet along with Tubes, Shell and Channel.

- Finite Element Analysis (FEA) for Lifting Lug, Tailing Lug along with full 3D Shell Model to evaluate compressive stresses in Shell and Local Stresses on Lug to Skirt and Dish junction.

- Analysis of Hot box along with Y ring to Shell, Skirt and Dish end junction for Seismic, Operating and Design conditions.

- Creep Fatigue Analysis of Chrome Molybdenum Reactor using ASME CC 2605 to evaluate the Creep & Fatigue Damage.

- Low Cycle Fatigue evaluation of Partition Plates of Ammonia Converter Basket.

- High Cycle Fatigue Evaluation of Agitator Vessels.

- Fatigue Damage Evaluation for Coke Drums.

- Local PWHT analysis of closing seams for Coke Drum to set the optimum rate of Heating/Cooling to reduce the developed stresses during local PWHT.

- 3D sector Modal Analysis of Shell Flange, Cover with double conical gasket.

- 3D sector modal analysis of Shell, Dish end junction for radial and offset nozzle.

- Support structure analysis for various Reactors and Vessels.