Welding

- We are equipped with a state-of-the-art welding facility to execute

- All kinds of complex welding engineering applications

- We have qualified International Welding Engineers with extensive experience in Critical Metallurgies

- Team of trained and Qualified Welders and Welding Operators to perform all complex welding operation

- We follow comprehensive welding Quality Management in accordance with ISO 3834 -2

-

- SMAW

- SAW

- GTAW

- FCAW

- ESSC

- GMAW

-

- SAW - Twin/Tandem/2G /,NG

- GTAW - Semi-Auto/Mechanised

- FCAW - Semi-Auto/ Mechanised

- SMAW - Double Welder Technique

- GMAW - Semi-Auto/Mechanised

- ESSC - Single Head/Twin Head

- Automatic Tube to Tube Sheet Welding

- Automatic Internal Bore Welding (IBW)

-

- Carbon Steel

- Inconel/Monel/Hastelloy

- Low Alloy Steel ( Conventional,Enhanced and Advanced )

- Titanium /HR 235

- Stainless Steel ( Austenitic , Ferritic, Martensitic , Duplex , Superduplex and Urea Grade)

-

- ASME Section IX

- ISO15614

- IBR

- IS

- AD Merkblatt

- API

- NACE

- NBIC

-

- ASME Section IX

- ISO 9606

- IBR

- IS

-

Narrow Gap SAW

-

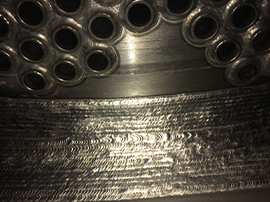

Tube to Tube Sheet Welding

-

Weld Overlay Inside Head

-

Weld Overlay Inside Shell

-

Mechanized Weld Overlay Inside Elbow

-

Internal Bore Welding

-

Small Bore Nozzle ID Weld Overlay

-

Tube Sheet Weld Overlay

-

Weld Overlay on Corner Area of Tube Sheet

Australia

Algeria

Belgium

Bolivia

Egypt

India

Indonesia

Kuwait

Kazakhstan

Mexico

Nigeria

Oman

Saudi Arabia

South Africa

Thailand

Trinidad & Tobago

Turkey

USA

UAE

United Kingdom

Uzbekistan