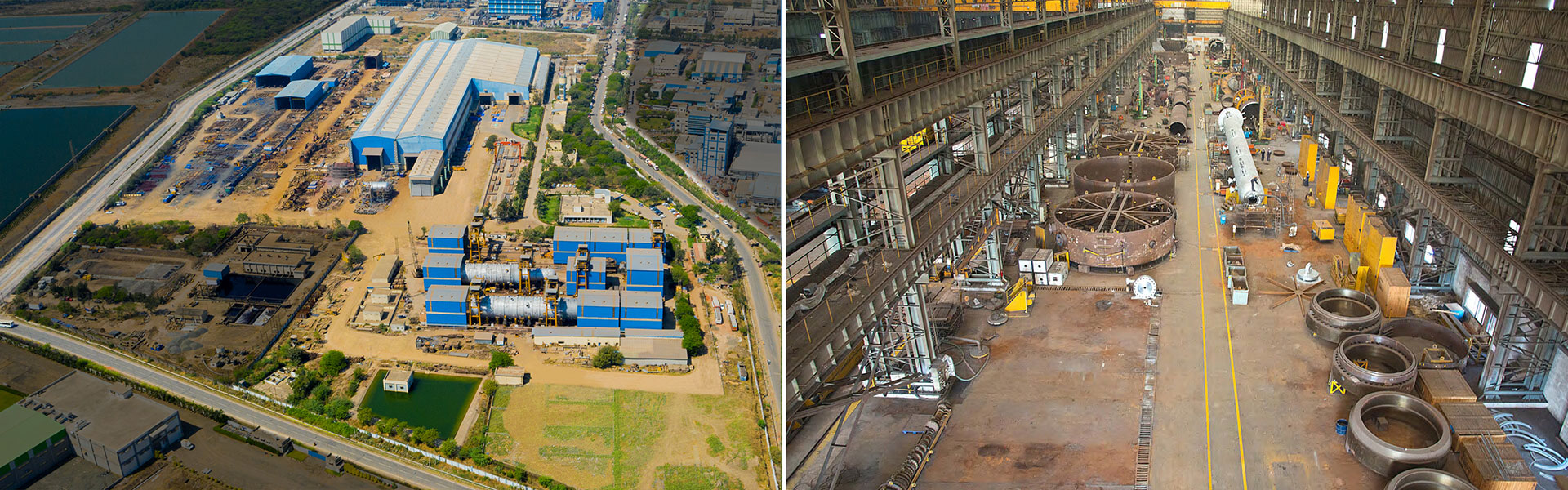

INFRASTRUCTURE

The indigenously designed unit can manufacture equipment ranging from 50 MT to 2400 MT and the specifications include:

- Single Piece Equipment Weight handling capacity: up to 2400 MT

- Capability for handling equipment up to 16 Meter Diameter X 120 Meter Length

- Multiwall Shell fabrication by using shrink fitting Technology

- Rolling Capacity: Up to 250 mm ( 10 inch) Thickness in cold condition

- Drilling Capacity: Thickness up to 1000 mm (40 inches) by using deep hole CNC Drilling Machine/ Dual Spindle Drilling

- Machining of Large Diameter Tube sheet up to 10 meters by VTL

- Post weld heat Treatment

- • Fixed Furnace Size: 13000 mm (Width) x 13000 mm (Height) x 26000 mm (Length)

- • Local Stress Relieving by Electrical Resistance Method

- • Stress relieving of large jobs in modular furnace . This furnace can be extended as per the size of the Job.

- CNC Plasma cutting machine for CS plates up to 300 mm thick and SS plates up to 110 mm

- Automatic Tube to Tube sheet joints welding

- Narrow Gap Welding with Seam Tracking

- Mechanized welding of head Longitudinal and circumferential seam

- Twin wire and tandem SAW

- Strip Cladding using single as well as double layer technique

- Strip cladding on nozzle , shell , head, and Tube sheet

- Mechanized weld overlay on small diameter nozzle and Elbow

- 03 Nos. Radiography Testing Enclosure

- Two Linac (6 Mev and 9 Mev)/ Radiography up to 450 mm thick

- Advanced NDE facility TOFD & PAUT

- Advanced ultrasonic testing on tube-to-tube sheet joint

- NDE personnel certification in line with ASME and PCN /ISO 9712

- NABL / ISO:17025 Approved Lab for Material Testing

- Shot Blasting & Painting enclosure

- RORO Jetty